Ductwork forms the backbone of any heating, ventilation, and air conditioning (HVAC) system. It is a network of passages designed to distribute conditioned air throughout a building and return air back to the system for reconditioning. Well-designed ducts ensure energy efficiency, indoor comfort, and proper airflow. Poorly designed or neglected ducts, on the other hand, can lead to higher utility bills, uneven temperatures, and compromised indoor air quality.

Different Types of Ducts in HVAC

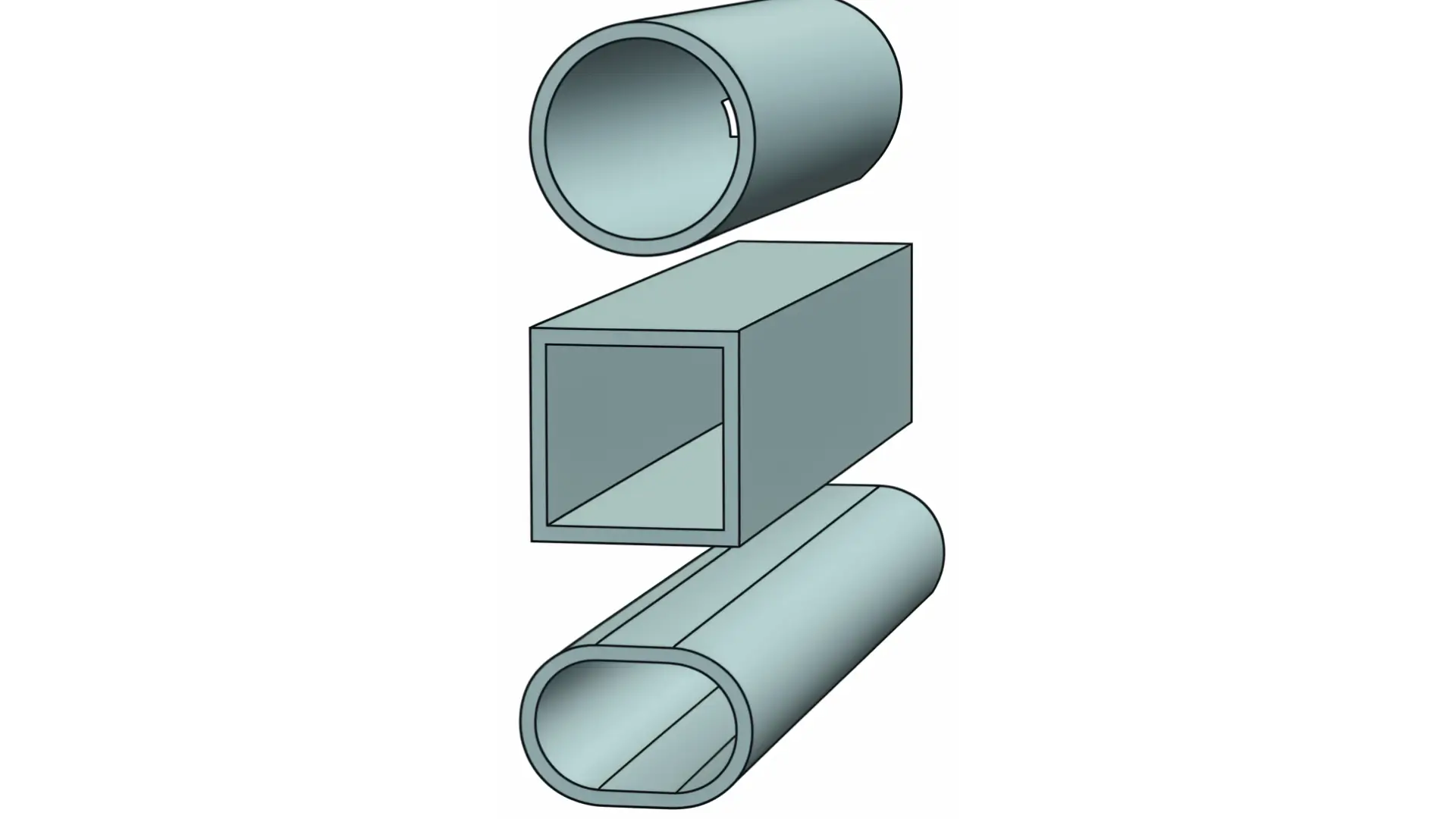

When homeowners and businesses consider HVAC design, they often ask about the different types of ducts available. Choosing the right duct material and shape directly impacts performance, efficiency, and long-term durability. Below, we break down the most common types of HVAC ductwork used today.

Types of HVAC Ductwork

1. Rectangular Ducts

Rectangular ducts are one of the most widely used in commercial and residential projects. They are typically fabricated from sheet metal and can be custom-built to fit tight spaces. Their flat surfaces make them easier to install against walls or ceilings. However, they have slightly higher resistance to airflow compared to round ducts, which may require stronger fans.

2. Round Ducts

Round ducts are considered the most aerodynamic option for HVAC systems. Their shape reduces air resistance, which means less energy is required to move air. They also experience fewer issues with pressure loss and are often quieter in operation. Round ducts are commonly made of galvanized steel, aluminum, or flexible plastic.

3. Oval Ducts

Oval ducts combine some benefits of both round and rectangular ducts. They are often used where ceiling space is limited but round ducts cannot fit. Oval ducts provide good airflow while maintaining a lower profile, making them useful for modern building designs.

4. Flexible Ducts

Flexible ducts are popular in residential systems, especially for connecting supply air outlets to rigid duct trunks. They are lightweight, easy to install, and made of a wire coil covered with plastic and insulation. While cost-effective, they must be carefully installed to avoid kinks or compression, which can restrict airflow.

5. Fiberglass Ducts

Fiberglass ducts are lined with insulation, which helps reduce noise and heat loss. They are often used in systems where soundproofing is important. However, they can be more difficult to clean and may degrade faster if not properly maintained.

6. Fiberboard Ducts

Fiberboard ducts are made from compressed resin-bonded fibers coated with a protective foil. They are affordable and provide natural insulation. However, they are less durable than sheet metal ducts and more prone to mold growth if moisture is present.

7. Fabric Ducts

Fabric ducts, sometimes called textile ducts, are used in large open spaces like gyms, warehouses, and commercial kitchens. Instead of rigid metal, these ducts are made of specialized fabric that distributes air evenly across the area. They can also be designed in different colors and styles, making them an aesthetic choice for certain installations.

Types of Duct Systems in HVAC

While duct shapes and materials are important, it’s also essential to understand duct systems within an HVAC network. These systems determine how air is distributed and returned throughout the building.

1. Supply Ducts

Supply ducts carry conditioned air from the HVAC unit to different rooms. Properly designed supply ducts ensure even distribution and maintain comfort across the entire space.

2. Return Ducts

Return ducts pull indoor air back into the HVAC system, where it is filtered, heated, or cooled before being recirculated. A well-balanced system includes both supply and return ducts in proportion to maintain air pressure.

3. Trunk and Branch Duct Systems

This system uses a large main duct, known as the trunk, with smaller branch ducts extending to individual rooms. It is one of the most common layouts in residential HVAC systems.

4. Hybrid Systems

Some buildings use hybrid duct systems that combine different materials and layouts to achieve maximum efficiency. For example, a trunk may be made of rigid sheet metal, while the branches use flexible ducts for easier installation.

Comparison of Ductwork Materials and Systems

When evaluating different types of ducts and systems, several factors come into play:

- Durability: Sheet metal ducts last longer than flexible or fiberboard ducts.

- Cost: Fiberboard and flexible ducts are more affordable, while sheet metal and fiberglass tend to cost more.

- Energy Efficiency: Round sheet metal ducts and insulated fiberglass ducts are more energy efficient.

- Maintenance: Smooth metal ducts are easier to clean compared to fiberglass and fiberboard.

Best Use: Fabric ducts are ideal for large open spaces, while flexible ducts are suited for residential connections.

A clear comparison ensures that the chosen ductwork aligns with the building’s size, purpose, and long-term efficiency goals.

Common Problems with Different Types of Ducts

Even the best-designed systems can face issues if not maintained properly. Common duct problems include:

- Leaks: Small gaps or holes can waste up to 30% of conditioned air.

- Poor Insulation: Heat loss or gain in uninsulated ducts reduces efficiency.

- Blockages: Dust, debris, or pest intrusion can restrict airflow.

- Moisture Damage: Fiberglass and fiberboard ducts are more vulnerable to mold growth.

Identifying and resolving these issues early prevents energy waste and improves indoor comfort.

Duct Maintenance and Cleaning

Routine maintenance is essential for every type of HVAC ductwork. Clean ducts help maintain air quality, extend system life, and ensure energy efficiency.

Signs that ducts need cleaning include:

- Visible dust or debris blowing from vents

- Musty or unpleasant odors when the system runs

- Uneven temperatures across rooms

- Increased allergy or respiratory issues indoors

- Professional duct cleaning and sealing can resolve these problems and improve system performance.

FAQs About Different Types of Air Ducts

What are the most common types of ducts in HVAC?

The most common types are rectangular, round, and flexible ducts, but fiberglass, fiberboard, oval, and fabric ducts are also used in specific applications.

Which type of duct system is most energy efficient?

Round sheet metal ducts typically provide the best airflow efficiency, while insulated ducts like fiberglass help reduce heat loss.

How long do different types of ductwork last?

Metal ducts can last 20–25 years with proper maintenance, while flexible and fiberboard ducts often need replacement within 10–15 years.

What’s the best duct system for homes?

For most homes, a trunk-and-branch duct system with a mix of sheet metal and flexible ducts offers durability and cost efficiency.

Conclusion

There are many different types of ducts and duct systems in HVAC, each with its own advantages and drawbacks. From rectangular, round, and oval ducts to flexible, fiberglass, fiberboard, and fabric options, the choice depends on space, budget, and efficiency needs. Similarly, supply, return, and trunk-and-branch systems form the foundation of proper air distribution in any building.

Selecting the right ductwork is not just about cost—it’s about long-term performance, comfort, and air quality. For professional guidance and duct services tailored to your building, consult an HVAC expert who can recommend the best solution.